Applications > Textile dyeing > Reactive dyes

This series are wool reactive dyestuffs with high performance. It contains double reactive groups, with its water fastness , high stability, good performance in wet fastness and free of heavy metals, can meet OeKo-Tex100 environmental demands.

Main features

Contains α-bromo-acrylamide active group, chromatography full, especially suitable for Wool worsted industry.

* Especially suitable for the dyeing of machine washable wool.

* Suitable for the dyeing of high temperature or boiling temperature.

* Good light fastness

* Stay with a high performance of High-wet because of solved by the Chlorinated water or shrinkproof.

* Can be combined with the Cationic dyes to dye the Wool/acrylic blended fibers.

| Color Sample | Product | C.I.No. |

|

Reactive Yellow 4G 100% | Reactive Yellow 39 |

|

Reactive Orange RG 100% | |

|

Reactive Red 2G 100% | Reactive Red 116 |

|

Reactive Red 3G 100% | Reactive Red 136 |

|

Reactive Red 6G 100% | Reactive Red 84 |

|

Reactive Red GN 100% | Reactive Red 446 |

|

Reactive Red B 100% | Reactive Red 65 |

|

Reactive Red 5B 100% | Reactive Red 66 |

|

Reactive Blue 3R 100% | Reactive Blue 50 |

|

Reactive Blue 3G 100% | Reactive Blue 69 |

|

Reactive Dark Blue B-01 100% |

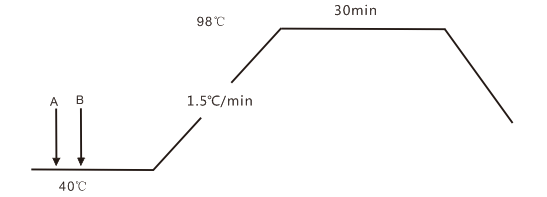

Technology of dyeing

(For example of Wool, only for reference)

Dye dissolved: Dyes beat with cold water, Stir in not more than 60 ℃ warm water to dyes completely dissolved, then Cooling & filter, join to the dyes vat.

Process of graphs

Dyeing prescription

A: Penetrant CA 0.5-1 g/l

Dye leveller B 1-2 g/l

Acetic acid x g/l

Adjust pH=4.5-7

B:Dyes X%

Washing crafts

Put the sodium carbonate or ammonium hydroxide to the dye bath, adjust the PH to 8-8.5, and keep 15-20mintues under the temperature of 80-85℃. Then fully washed it by cold water and adjust the dye bath to PH=5 by the acetic acid.

0577-86799090 86120111

0577-86799090 86120111